-

Glass Tempering and Bending Lines

Solutions for the flat and bent tempered glass products to meet the demands in architectures, furniture, household appliances, automobiles and solar energy industries. There are different series of equipments and over one thousand kinds of specifications and types. The machines have enjoyed great popularity in dozens of countries and regions in Europe, north and south America, Asia, Oceania and the Middle East.

-

Cutting Tables

Tilting cutting table with 3 interpolated axes for straight and shaped cutting of flat glass plates with thickness from 2 to 25 mm.

Fixed cutting table with glass transport belts, 3 interpolated axes for cutting panes of straight and shaped flat glass with thickness from 3 to 19 mm, normally in line with loader and cut off bench

-

Double Edger / Line

Double Edging Machine is suitable for grinding two straight-line edges of furniture glass, and electrical appliance glass and so on. It has characters of rapid speed and high brightness , The machine adopts high precision transmission structure with two linear guiding bars and two ball bearing guide screws. It is equipped with PLC system and superior HMI screen to guarantee convenient and comfortable operation

L” Shape Automatic Production Line – Lifting Structure

Composition: Two Double Edging Machines and One L-shape Automatic Transfer Table; the structure is simple and stable, also it is for floor area saving.

It can process the four sides at one time.

The automatic transfer table takes lifting structure, it is widely used for all types of glass, big or small, thick or thin, and takes advantages of high transferring efficiency and flexible con figuration.

-

Washing Machine

This washing machine is an easy-to-use machine. Carefully conceived and designed for those who need a machine for efficient washing and drying with practically no maintenance costs. All parts in contact with water, including the washing and transport roller shafts, are made of stainless steel ensuring this machine a quality and duration which is clearly superior to the competitive machines of the same range

The vertical washing machine can be used in stand-alone, in line with other machines like straight-line edgers or sandblasting machines or it can be installed in double-glazing production lines with low productivity. Horizontal washing machine also used stand-alone before tempering, in line with double edger or screen printing lines or lamination line.

-

Insulation Glass Production Lines

It is with numerical control, driven by brushless motors and ball screws for fast and precise cycles, offering high level performances. The press can be opened in order to facilitate maintenance. Double / Triple panels can be done

Butyl extruders

Butyl extruder for application of primary seal; 1kg model for small production runs and 7kg version for standard production runs.

Spacer bar cutting machine

Cutting device with electronic measurement control for spacers cut-to-size

Spacer bar bending machine

Aluminium spacers bending tool Manual press

Automatic Spacer bending machine

It can bend both the arc and shaped aluminum spacers

Desiccant Loader

Loading system of desiccant salts for aluminium spacers; tilting function for faster loading. 20 spacers may be loaded simultaneously

Rotating Table

Rotating table for hand sealing of glass panels of the following size: from 200x200mm to 1000x2000mm. Pedal controlled start-stop function

Sealant Pump

Auto Sealing Robot

Automatic sealing for different size rectangle Insulating glass, high quality sealing effect. Automatic corners finishing by sealing gun wiper. Special synchronous belt conveyor preventing the machine from contamination by the sealing agent. Automatic detection of IG thickness and spacer depth, adjust accurately the nozzle position and sealing amount

Demineralisation Units

Demineralisation unit with two-stage reverse osmosis for the production of demineralised water.The product range comes with storage tank, automatic filling system,water quality control system, alarms.

Different models are available with different production capacity: from 30 l/hr to 190 l/hr

-

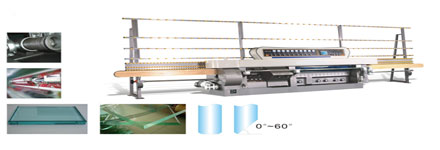

Vertical Bevelling

-

Vertical Glass Edging / polishing machine, Vertical Glass Mitering machine

Straight-line glass polishing machine / glass edging machine - it is available with 8 to 12 wheels.Straight line Glass Mitering machine 0-60 with 9 to 12 wheels

-

Shape polish machine

-

Drilling machine / Milling

Milling: Working center with three axes for automatic execution ofmilling and grinding of notches. It is featured by the ease of use, quick programming, and the benefit is the speed and the precision of the processes. Its simple and solid conception requires very low maintenance.

-

HST (Heat Soak Test)

The Heating Soak Test Furnace was designed and manufactured according to European safety performance test standard of toughened glass, energization and electricity stoppage of heater achieved by PLC controlling the solid state relay; technological parameter and program control use computer memory saving and intelligent control, temperature adjustment mode is automatically accomplished by PLC control system; automatic storage of temperature curve and print test report of every furnace; there are altogether 12 sets blowers to form forced convection circulation system of hot wind, in addition, fitted with 3 sets inverter blower used for automatic control of cooling rate of unit; 22 sets of thermocouples dispersed in heating furnace used for supervising temperature status of different regions, computer interface display at right time

-

Sandblasting Machine

-

Laminating furnace

Producing Laminated Glass automatically,Frequency adjust speed, fixed position automatically and precisely. Whole equipment with CE certification

-

Cutting Plotters (Vinyl cutting for sandblasting the glass to make designs)

-

Belt Arrising Machine